ultraFAIMS™

Ion mobility as an in-source separation method for mass spectrometry

- Additional high speed separation stage, orthogonal to both chromatography and mass spectrometry

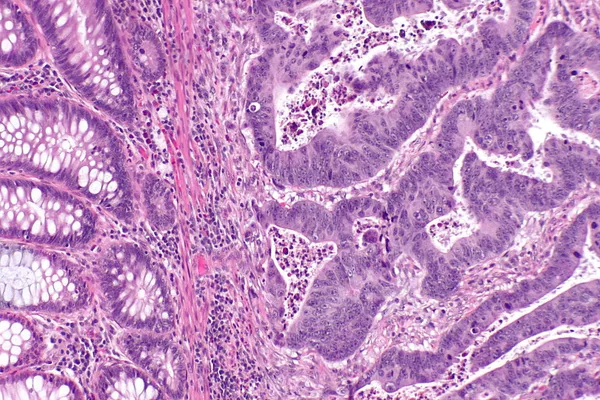

- Separate isomeric interferences and reduce chemical noise for mass spectrometry imaging and untargeted omics applications

| As of September 2021, ultraFAIMS has been discontinued and is no longer available to purchase. If you are interested in using FAIMS for VOC detection contact us to find out about our current capabilities. |

OVERVIEW

What is ultraFAIMS?

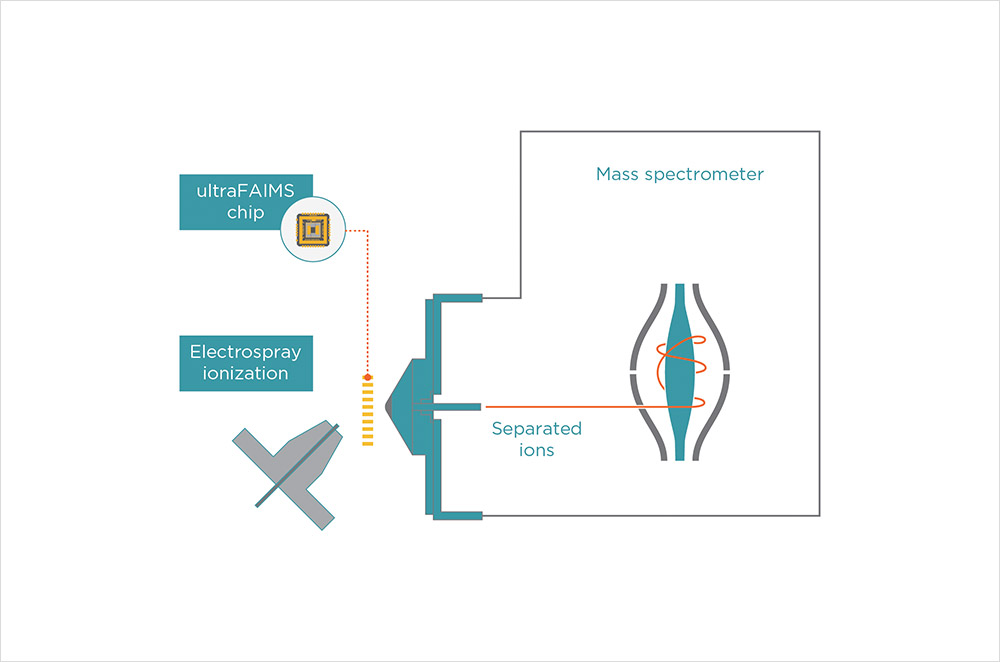

ultraFAIMS is an ion mobility spectrometry device, consisting of a miniaturised chip that is mounted between the ionisation source and the mass spectrometer inlet. The ionisation source operates as normal, and ions are then pulled through the ultraFAIMS chip by the gas flow into the mass spectrometer

ultraFAIMS uses field asymmetric ion mobility spectrometry (FAIMS), a form of ion mobility spectrometry (IMS) analogous to a quadrupole mass analyzer, where electric fields can be applied to selectively filter certain ions through the device.

HOW IT WORKS

What differentiates ultraFAIMS from other FAIMS technologies?

The key to the ultraFAIMS difference is the unique chip-based design, which has enabled the analytical gap width to be reduced to 100 µm with a channel depth of 700 µm.

The primary benefit to this reduction in size is the speed of separations that can be acheived.

- The ion residence time is < 250 μs, ~ 100 times faster than previous FAIMS devices.

- The lower settling time associated with the low-voltage drive electronics means field settings can be switched more quickly.

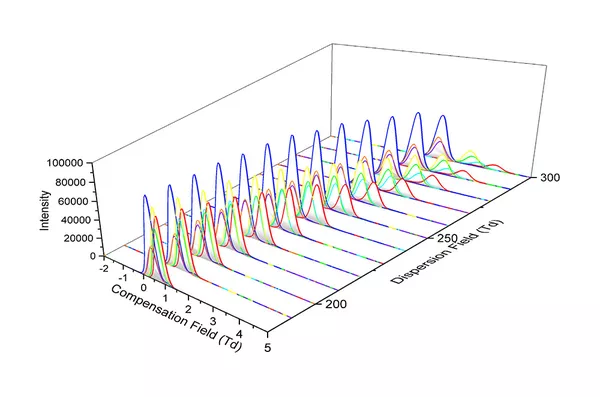

These factors mean that full FAIMS separation sweeps can be carried out in < 1 second, allowing real time LC-FAIMS-MS analysis, or the fields rapidly stepped through selected values with millisecond response times to allow filtering to be synchronized with multiple reaction monitoring transitions.

Another important benefit of the reduced size is that the voltages needed to produce the higher fields are actually much lower than in macro-scale FAIMS instruments. This means dispersion fields in the ultraFAIMS system reach twice the field strength of previous devices offering a new regime for finding differences in mobility between the high and low-field portions of the cycle.

PROCEDURES

Integrating with existing mass spectrometry workflows

The electric fields applied to selectively filter certain ions through ultraFAIMS can be exploited in two ways:

First, ion species can be selectively transmitted by operating the ultraFAIMS electric fields at a fixed value, using ultraFAIMS as a tunable filter. This makes ultraFAIMS ideal for targeted analysis, allowing target ions to be selectively transmitted to the mass spectrometer.

Alternatively, ultraFAIMS can be operated in scanning mode, where the compensation field (CF) is dynamically changed at very high speed, producing a spectrum of ions separated on the basis of differential mobility. CF scanning allows generation of CF spectra, where the abundancy data is plotted against CF. For each compound there will be a peak in the FAIMS spectrum centred on an optimum CF to allow an ion to pass through the device.

- INLET GAS FLOW RATE

Optimal range for standard ultraFAIMS chips is 1-2L/min (lower and higher flow rates are possible, but may require a custom chip design)

- OPERATING TEMPERATURE

Must be stable for good performance, limited to 150°C at chip region

- IONISATION SOURCE TYPE

Any atmospheric pressure source should be compatible – for liquid-phase sources such as ESI the interface design must ensure good ion desolvation upstream of the chip

- VOLTAGES

Voltages The system is compatible with inlet voltages up to +/-6kV

- MATERIALS

Materials present in the source region are gold-plated nickel, Rogers 4350B ceramic, stainless steel 316, PTFE, PEEK and Macor ® ceramic (plus a small amount of solder)

- LIQUID FLOW RATE COMPATIBILITY

Tested from 50nl/min to 0.5ml/min